FormRep 3D Print Service

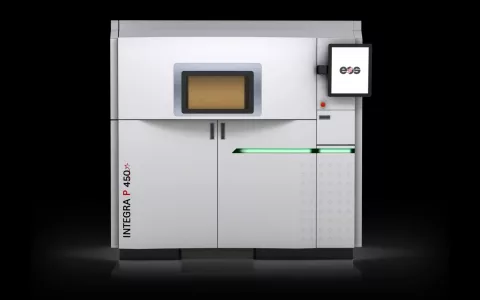

FormRep’s 3D printing services utilizes modern equipment and certified processes. Let our team work for you to get the best quality prints on a timeframe that works for you. We specialize in EOS SLS laser printing, HP MJF printers, and EOS DMLS printers. With rapid execution, FormRep aims to be the #1 3D Printing Service in the USA.

The FormRep Difference:

Made in the USA

Experienced Team

Modern Equipment and Processes

ISO Certified

Dedicated Success Manager

3D Printing is best suited for:

Small batch production, including prototyping

Intricate designs with gaps or holes in the middle

Design changes, even during production

Lower cost for prototypes and small batches

Industrial 3D Printing Processes

Multi Jet Fusion (MJF)

MJF offers cost-efficient material with industry-leading surplus powder reusability. Engineered for HP Multi Jet Fusion technology, the HP 3D High Reusability PA 12 and thermoplastics test the limits of functional part creation, optimizing cost and part quality, while also delivering high and, in many cases, industry-leading reusability at a low cost per part.

FormRep 3D Print Material Options

SLS Nylon – White powder sintered together with a laser. High-dimensional accuracy and good strength qualities. Can be dyed any color with more vibrant bright colors. Wall thickness recommendation is 1mm.

MJF Nylon 11 – Ink Jet sintering that provides a raw ash grey part. Thermoplastic material delivering optimal mechanical properties. Best parts are black but colors can be used with a darker based and some inconsistences. Wall thickness recommendation is 1mm. PA 11 is ideal for producing ductile, quality, functional parts.

MJF Nylon 12 – Ink Jet sintering that provides a raw ash grey part. High-dimensional accuracy and high strength qualities. Best parts are black but colors can be used with a darker based and some inconsistences. Wall thickness recommendation is 1mm. PA 12 is ideal for producing strong, functional, detailed complex parts.

MJF Full Color – Ink Jet sintering that provides a full color part matching the colors defined in the uploaded .3mf file.

MJF Polypropylene – Ink Jet sintering that provides a raw ash grey part. Polypropylene is a versatile material ideal for a wide range of automotive, consumer, industrial, and medical applications. Wall thickness recommendation is 1mm.

TPU – A rubber like plastic that is sintered together with a laser at low temperature. High-dimensional accuracy and very strong. Recommended to have wall thicknesses of at or above 0.75mm. Can be dyed any color. Good for soles, padding, cases, protective gear and clips.

MJF Glass-Filled Nylon – Ink Jet sintering that provides a raw ash grey part. Glass-Filled provides more rigidity for stronger parts. High-dimensional accuracy and high strength qualities. Best parts are black but colors can be used with a darker based and some inconsistences. Wall thickness recommendation is 1mm.